Welcome To Zuberi's Molding and casting Page

The assignment this week is to machine and make a mold and cast parts from it. I wanted to do something fun this week so I decided to cast dominoes.

People playing dominoes.

Design drawing in paint. I took this design and created a 3D image in Sketchup. Then I exported the .stl file to OpenSCAD. OpenSCAD program basically builds a block around your model, subtracts the object leaving a negative, then divides the block in half leaving you with a 3D mold that you can sill to cast your original object. Great program as long as you keep in mind that with the extra step you want the positive in the wax so you'll get the negative in the mold and you'll be able to cast the original object.

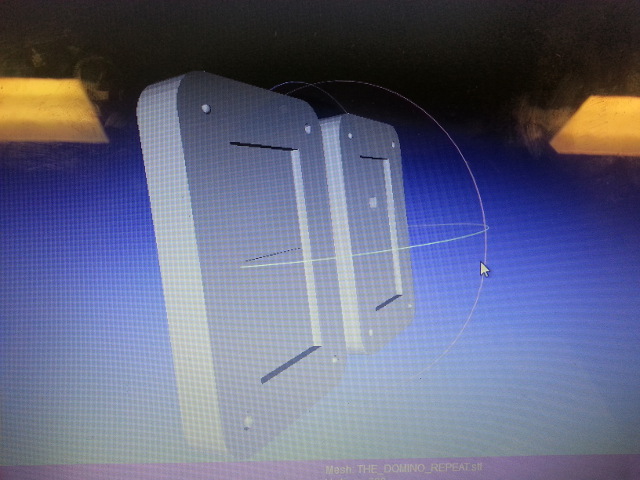

My 3D design for the mold. When I took my OpenSCAD mold to the machine at first, I was not able to convert it from .stl to .rml in fab modules because the .stl file was not binary. MeshLab allowed me to open the file and export it as a binary .stl file. Others with this issue will be interested in this work-around. You can download MeshLAb for free online.

The mold ready to cast single pieces. No problems mixing the Oomoo.

I had a few more problems in the casting stage. I didn't make a second hole for air at first, so I had to cut one after it was molded. Also, I did not mix enough Hydrostone so I had to make another batch after I had already started pouring. I guess this is why I ended up with airholes at the end. Also, I got the ratio of Hydrostone to water wrong at first because I had 100 parts water to 22 parts Hydrostone instead of the opposite. The Hydrostone is easy to work with if you follow directions, and it dries pretty quickly.

The domino was perfect except for the airholes in the back side which were due to my mixing miscalculation. I recommend the practice of pouring with a very small stream which did remove most of the air bubbles from the mixing process.